Meet The Scientist Devoted To Keeping Cars Shiny

Show us a petrolhead who’s never wielded a wet sponge in anger and we’ll show you a flying pig. Even if you’ve never owned a car, there’s a good chance you were conned into cleaning your parents’ car in exchange for cold hard cash or a couple of biscuits and a PlayStation game. But have you ever actually stopped to think about what you’re spraying, rubbing or splurting on to your car?

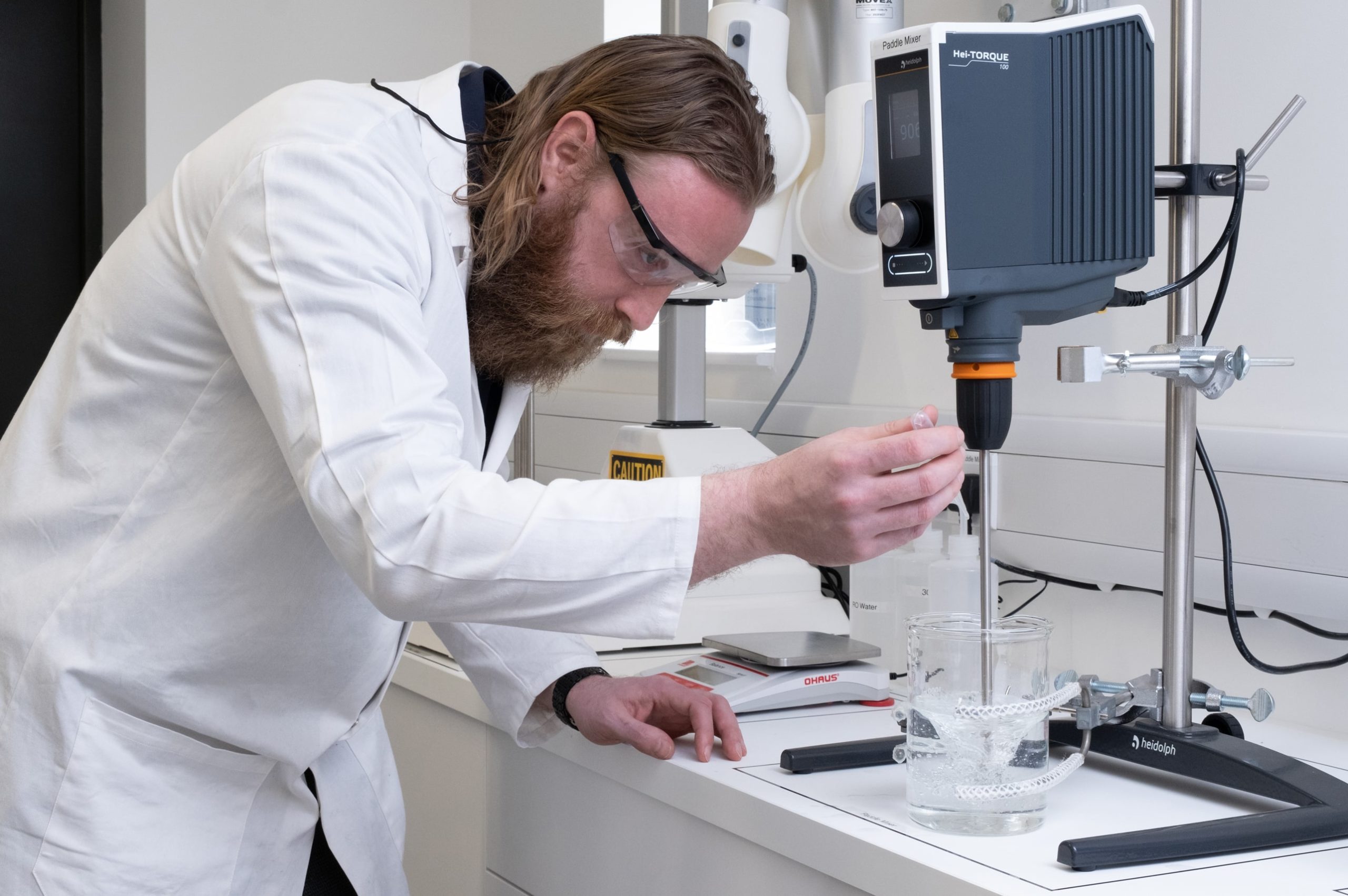

We realised that we’ve never actually thought about what goes into car cleaning and protection products, so we spent a morning at Gtechniq’s headquarters to meet their Senior Formulation Chemist, Mr Lee Kennedy.

Lee’s background isn’t in cars – although he drives a bright-white VW Tiguan that’s proved useful for testing out his latest concoctions – instead he’s a qualified master chemist. He started his career working with soaps, detergents and wetting agents before moving into jobs working with coatings – before bringing both parts of his experience to work on car care products at Gtechniq.

It’s his job to improve the Gtechniq products that hundreds of thousands of car enthusiasts have applied to their cars – and he works on a microscopic level.

We met him in his brand-new laboratory on the ground floor of Gtechniq’s Northamptonshire facility – a huge hangar of a building where Gtechniq’s products are developed, made, marketed and distributed, all under one roof. The company’s 20 years old this year, and it’s at a point where it’s turning from cottage industry done-good into a hugely successful global business – hence Lee’s recent appointment.

WHAT CHEMISTRY GOES INTO DEVELOPING CAR CLEANING PRODUCTS?

We quickly learn that the stuff that goes into cleaning products is constantly changing and improving as new cleaning technologies are discovered. “Then it’s a case of evolving our existing products and finding new ways to improve their characteristics,” says Lee. This could be anything from improving the water resistance of a coating product, to increasing the dwell time of a snow foam to help it cut through dirt more effectively

“Car cleaning products share many principles with basic paints,” explains Lee. “We want them to stick to things, be water repellant, resistant, and easy to flow onto a surface.” It’s then a case of mixing additives and chemical ingredients in different amounts and subjecting each formulation to testing which can also accelerate real-world conditions to see how long the coating will last.

THE SCIENCE OF BEADING

A look around Lee’s lab shows that this is car cleaning backed up by a huge amount of science – we’ll give you a more in-depth tour in a later article.

Here you can see a tiny drop of water being dropped onto a plate that’s been coated with a Gtechniq product…

One example of the lengths Gtechniq goes to, to ensure customers and detailers have the best tools at their disposal sits in a busy corner of the lab. Here, Lee and his team have a machine to measure the contact angle of individual beads of water – a technical way of analysing how well a coating protects a surface on a microscopic level by looking at the angle a bead of water meets the surface. Think of a blob of water on a bonnet – look at it from the side and you might see the contact point is ‘tucked in’. This means the surface is hydrophobic and the water tries to stick to itself rather than the surface.

You might just think your car looks great on the ‘Gram when it’s covered in water beads after a wash, but the extent to which that happens is decided in the lab. Making a coating too hydrophobic (so the water runs off) can mean the coating itself is visible, which sort of defeats the point of an invisible coating.

… this is the same bead from the photo above. Note the lines drawn either side of it to measure the contact angle of the bead – steeper is better (up to a point)

“Another thing we measure is roll-off angle,” explains Lee. This is a measure of how steep a surface must be before water rolls off it – the test examines how well a coating can help shed water from a windscreen, for example.

IT ALL STARTS IN THE SCRAPYARD

Lee and his team spend their workdays testing and refining formulas – and a friendly local scrapyard often comes in handy. “We’re always able to go down and pick up some bonnets to test new formulations on to make sure the application behaves okay, to give us confidence it’s not going to do any damage,” says Lee. Once the team’s happy, they’ll pass them to Adam, Gtechniq’s in-house detailer, to use on Gtechniq’s staff cars.

very product goes through extensive testing before it makes its way onto a customer’s car

Lee says: “If you look at the Managing Director’s car [a stunning grey Alfa Romeo Giulia Quadrifoglio] in the rain there’s loads of squares across the front of his bonnet of different materials, where we’ve been testing the hydrophobic performance. I don’t think he minds.”

COMPETITOR ANALYSIS

It’s fair to say that the world of high-end car cleaning products moves at a serious pace, and the Gtechniq lab team analyses every competitor product that comes onto the market. There’s a corner of the building that has shelves packed with everything from fabric cleaners to ceramic coatings from around the world, each shelf divided into consumer, prosumer and professional-application-only products. “There’s only so much we can do to analyse competitors’ formulations – it’s proprietary information after all – but we’re mainly looking at performance levels,” explains Lee.

“You can have two completely different formulations that do the same thing. So for snow foam, we’ll look at dwell time, cleanability, how much dirt removal is there. We’ll score each criteria and see where we can improve ours to give the best product performance.”

WHAT AN ODDLY SPECIFIC JOB

Lee at work with his beloved paddle mixer

So, next time you’re waxing and ceramic coating your car to make it shiny and bead water like a duck’s back, think of Lee and his car-cleaning lab.

Word and Images credit – Tim Rodie @ Drive Tribe.