Behind the Scenes

If you’re anything like me, you probably assume that car cleaning products are a bit like the McDonald’s Big Mac – the recipe’s been nailed, and so it stays the same forevermore. While that may be true for some car-care brands, Gtechniq’s been doing things slightly differently since it started producing ceramic coatings for professional detailers back in 2001.

While some cleaning companies are happy to settle on a formula and will just sell the exact same product until the next ice age, there’s a small team at Gtechniq’s HQ near Northampton, UK that is constantly trying to improve the company’s products.

Gtechniq was originally founded by a quantum physicist, so it’s probably no surprise that the company uses constant lab testing of their own and competitor products to help make cars shinier. We took a quick look around Gtechniq’s lab to see how they work – this is what we found.

The fancy set of scales with a lid is a moisture balance – used to accurately dry and measure ingredients and products

Giving me a tour of the lab is Gtechniq’s Senior Formulation Chemist, Lee Kennedy. “The first area you come to in our lab is an area where we run basic checks on materials as they come in.” All the equipment is lined up on a pristine white work surface like a rank of stormtroopers, each in its own outlined and labelled space.

“First we use a pH meter to check how alkaline or acidic it is, which is mostly useful for decontaminant products – if the pH is too high you risk damaging the coating, if it’s too low it’s not going to strip grease off.”

Next Lee points me to what looks like the fanciest set of kitchen scales you’ve ever seen – something that’s also key to the lab’s work running quality assurance on Gtechniq products as they come off the production line. “This is a moisture balance,” Lee explains. “You put some product on it, then it heats it up to evaporate off any liquid to give you a really precise measure of a product’s mass – we use this to check a product is made up of the right amount of each active ingredient.”

DON’T BE A DRIP

Along the bench from the fancy scales sits a simple bench stand that holds something called a Ford Cup, which for all the world looks like a posh urine sample cup hewn of solid aluminium. “This is a simple bit of kit,” explains Lee. “You fill it up with product, then release it through a little hole on the bottom and time how long it takes to empty – it measures the viscosity. With things like ceramic coatings it’s very important to get the flow behaviour right so it applies correctly to your car.”

MAGIC MIXING

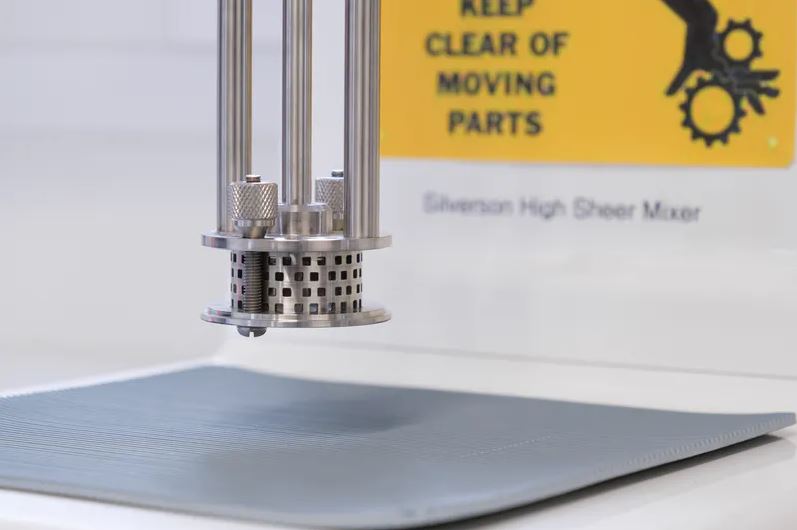

The high-sheer mixer can spin at 12,000rpm. Mary Berry would use it to make the world’s most furious Victoria Sponge

Near the end of the first bench lies Lee’s pride and joy – the high-sheer mixer. He beams with delight as he explains what this jumped-up KitchenAid does. “This is an absolute beast – it’s an extremely powerful very high-end blender, essentially.

The business end of the high-sheer mixer sucks in whatever you’re mixing and properly shreds it

“It spins at up to 12,000rpm, and whatever you’re mixing is forced through the little gaps in the attachment, shredding the ingredients apart. When you have two materials that don’t really want to mix together, this will persuade them!”

NO SCRUBS (GET A MACHINE TO DO IT FOR YOU)

On the next bench over sits a curious box that holds sheets of painted bodywork with two yellow sponges looming ominously above. “That’s a scrub machine,” says Lee. “It simulates washing your car every week for 3 years – we can simulate that in a couple of hours, it simply rubs the bodywork as many times as we tell it to. When we give customers an example of how durable a coating is and how long it’ll last on your car, this is how we test that.”

This machine quickly simulates years and years of car washing – in my case, maybe one entire wash…

The guys also have a salt spraying machine tucked under the table, which gets used to test Gtechniq’s range of marine products, but can also mimic driving through a harsh British winter littered with salted roads. “We can get four to five years of salt exposure done in 48 hours or so,” says Lee.

TENSIOMETER

…the image is then displayed on a computer which can measure the contact angle to show how good the beading is… with science

Word and Images credit – Tim Rodie @ Drive Tribe.